Alu Boss

Alu Boos plate information:

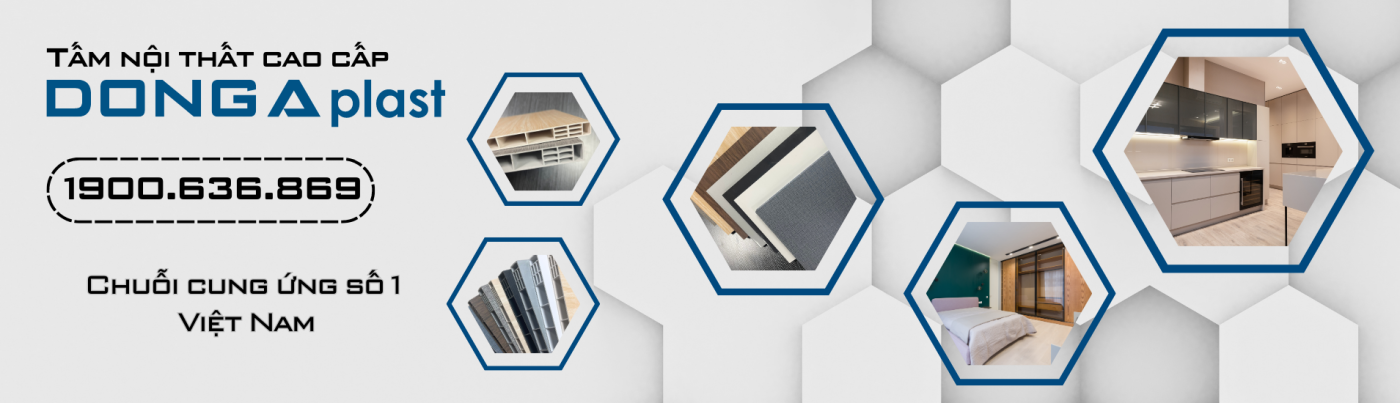

Product code: Composite Alu Boss sheet

Specification: 1220mm * 2440 mm

Thickness of aluminum surface: 0.05mm – 0.08 mm

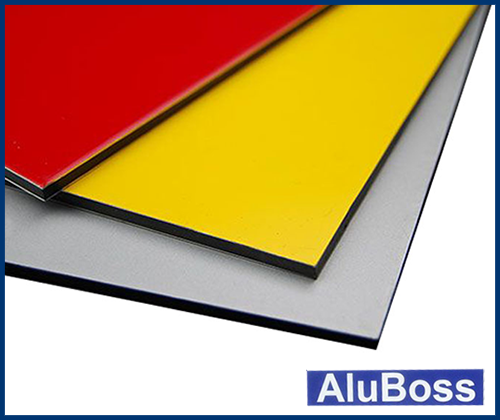

Colors: Diverse

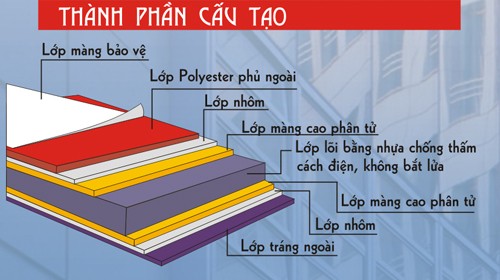

Material: The top and bottom are corrosion-resistant aluminum films, the middle is Polyethylene (PE) which is bonded to the surface by the polymeric membrane

Alu Boos plate application:

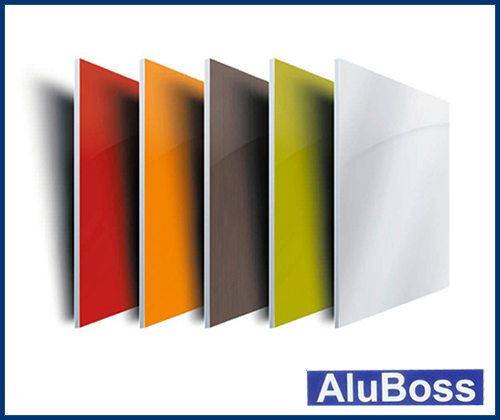

Used for construction and advertising, interior decoration. Interior decoration: billboards, hotel facades, supermarkets, railway stations, apartments, offices

Characteristics of Alu Boos:

The product is durable over time thanks to other features such as corrosion resistance and weather adaptability; withstand impact from temperatures from -50oC to 80oC

Description of Alu Boos

Alu DAG composite sheet is a composite aluminum plate of many colors, patterns, easy to clean and limits heat transfer. Products are chosen by the consultants because the advantages bring the perfect beauty of the era to the interior space of all projects, especially fast, simple and easy construction time.

Warranty: 2 years

ADVANTAGES OF ALUMINUM ALUMINUM – ALUMINUM COMPOSITE:

– About the form of aluminum alloy plate that meets the high requirements of users. It is a rich color variety, aluminum alloy plate with over 30 colors for customers to choose. From basic colors to metallic colors, antique brick imitation colors, wood vein, marble vein, marbe.

– Construction: aluminum panels are convenient and save a lot of costs, because when used as wall tiles, there is no need to plaster and paint. Aluminum alloy plate can be bent to execute the arches, round columns, corners…

– Technically, aluminum cladding panels fully meet the standards of moisture, heat insulation, sound insulation, fire resistance, material durability …

Used for modern constructions with high aesthetic, diverse colors, ensuring gloss, color fastness. Lightweight, easy to install,  good insulation and heat resistance (can withstand temperatures from -500 C to + 800C). Low expansion coefficient, waterproof, no warping, shrinkage, convenient in maintenance, cleaning.

good insulation and heat resistance (can withstand temperatures from -500 C to + 800C). Low expansion coefficient, waterproof, no warping, shrinkage, convenient in maintenance, cleaning.

INDOOR ALUMINUM PLATE

Suitable for ceiling and wall cladding, diverse colors, low expansion coefficient, fireproof, waterproof, soundproof, good thermal insulation. ensure color fastness and high aesthetic criteria, create spatial effects, not plastering and painting, reducing installation costs.

DECORATIVE ALUMINUM PLATE

Used for decorative cladding inside or outside the building, used for making boards, billboards, rich colors, variety, gloss, durability, good insulation, easy to clean, always kept Beautiful gloss, creating high aesthetic effect in decoration. Products are super light in size, easy to install, reduce construction costs, safe to use.

VIETNAMESE PREFERENCES

Form: Aluminum composite panels meet the high requirements of the user. It is a rich variety of colors, aluminum alloy panels with more than 30 colors for customers to choose from, from basic colors to metallic colors, imitation brick colors, wood grain, marble pattern, marbe stone …

Construction: Aluminum alloy composite panels convenient and save a lot of costs, because when used as wall tiles, shorten construction time, not plastering and painting. Composite aluminum alloy plate can be bent to construct the arches, round columns, corners…

Technical: Composite aluminum alloy panels fully meet the standards of moisture, insulation, sound insulation, fire resistance, high material strength …

INSTALLATION PROCESS:

1. Aluminum sheet is cut by horizontal saw, circular saw, and circular saw.

2. You can use a special shears, scissors or saw to discharge aluminum sheet.

3. Aluminum sheet can be bent by cyclone machine.

4. The aluminum plate hole is made with a special drill or chisel.

5. The aluminum plate can be painted or printed with different colors.

6. Links can be by self-tapping screws or rivet rivets.

7. Can be slotted to connect two aluminum plates together.

8. Screws / rivets can be used to join two aluminum plates or link on other surfaces.

9. Aluminum sheet can be cut into various sizes.

APPLICATION

Using composite aluminum material for exterior finishing, bringing high aesthetic efficiency and durability to public works such as buildings, shoowrooms, offices … Aluminum composite is used for interior and exterior decoration in buildings. build. Used to cover the hall ceiling, canopy, house facade.