Alu Composite DAG

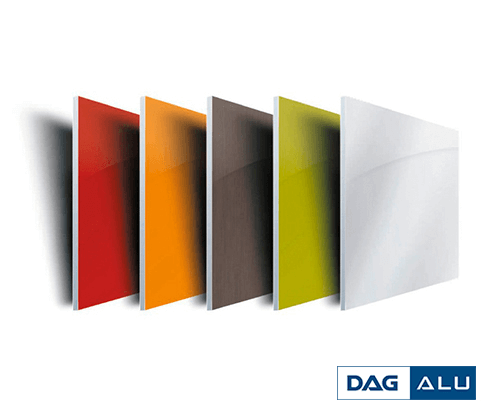

In order to meet the increasing demand in the construction sector, the world has created a breakthrough product technology, that is aluminum composite panels – plastic, also known as aluminum COMPOSITE. Thanks to the preeminent functions, this product has created a new style – luxurious and modern for all buildings.

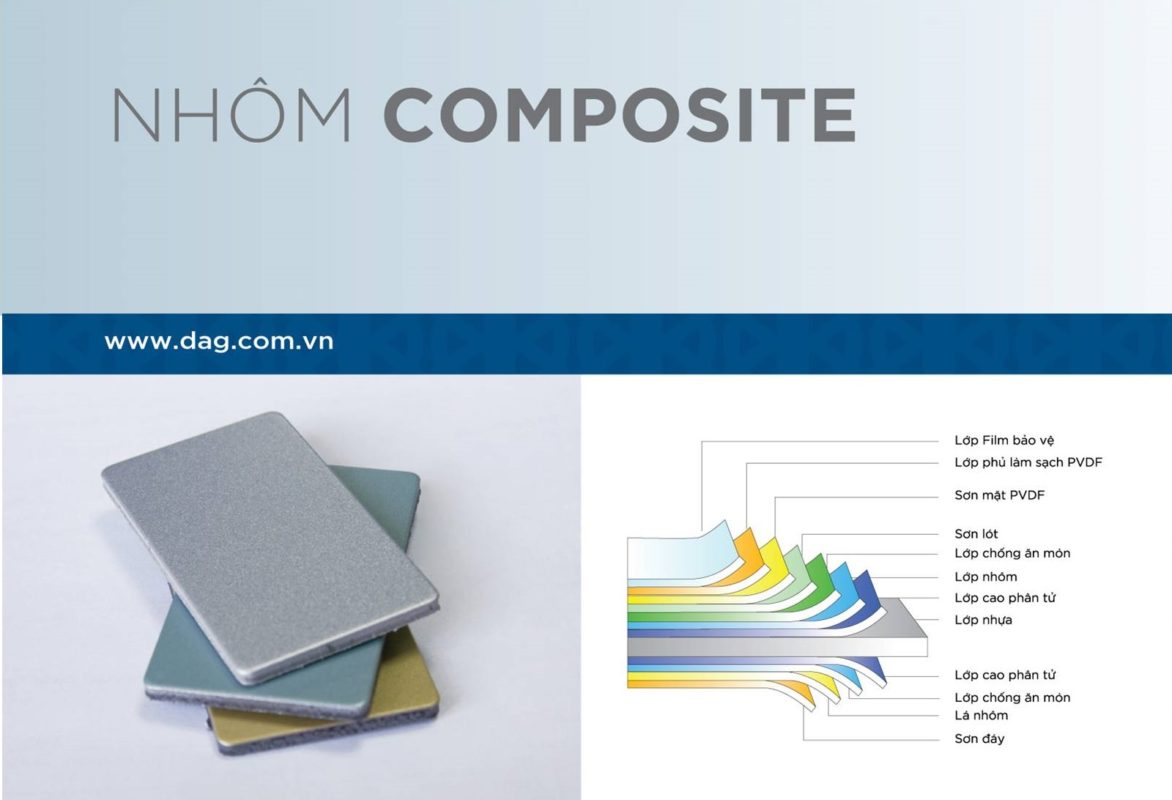

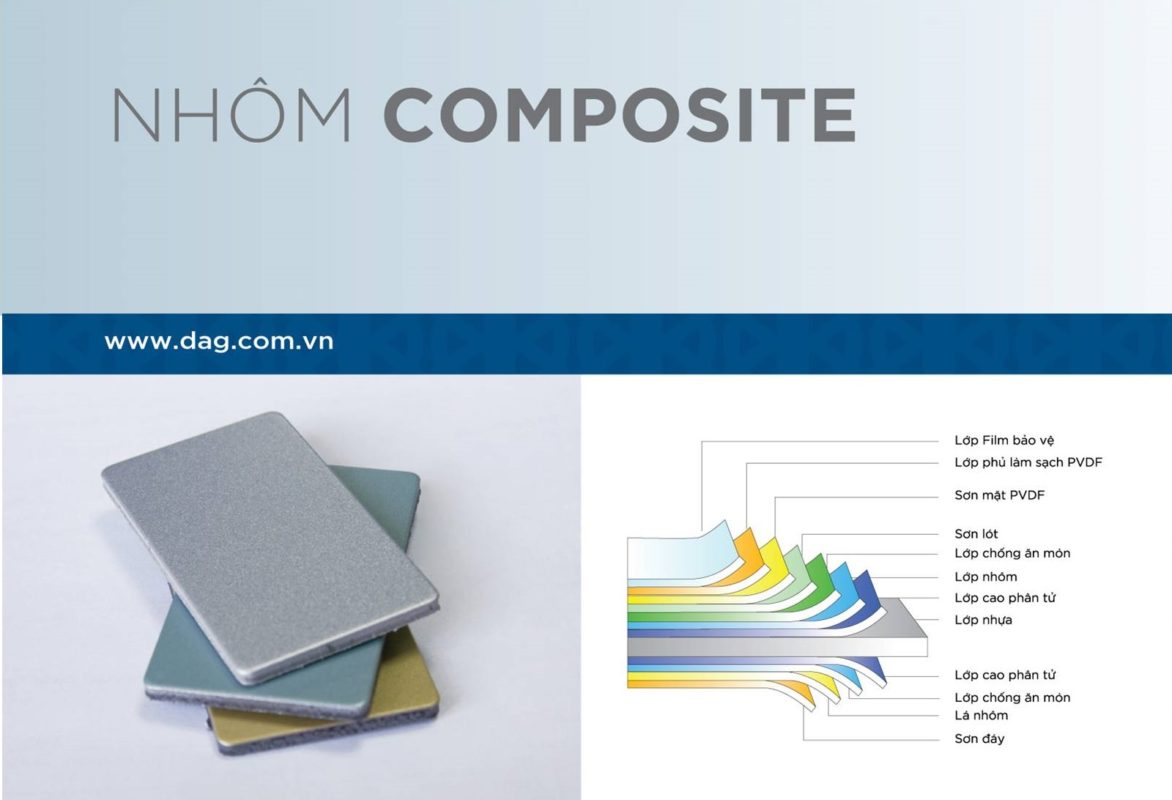

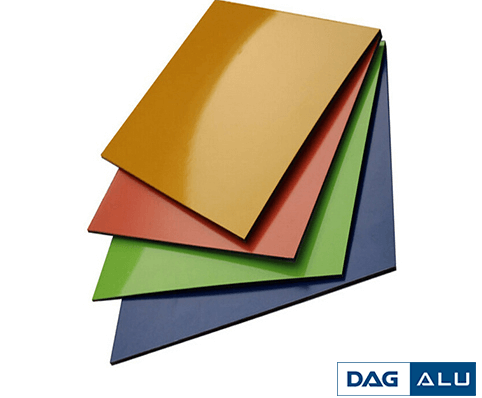

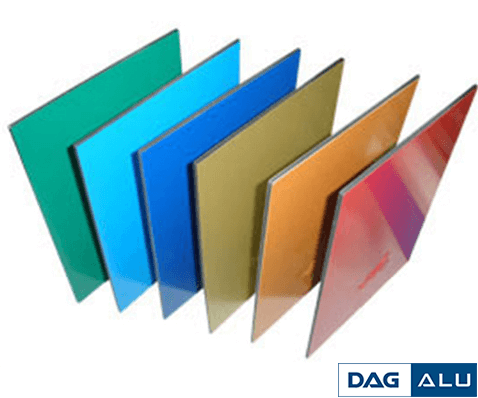

– Product features are superior insulation and heat resistant (from -50oC to + 80oC), better advantages than other materials such as steel, aluminum net, plywood, … Besides, aluminum composite panels with two layers of aluminum on both surfaces is fire-resistant, water-proof, highly resistant of chemical corrosion. Instead of using paint walls (repainted periodically), the aluminum composite panel which is seen as a replacement, is colorfast and low coefficient of expansion. The only one thing that users need to do is cleaning.

– Composition between 2 aluminum layers is PE, so you can bend easily during the construction period, easy to saw, cut, drill, trench cutting without peeling or scratches

– Standard size: Size 1220mm x 2440mm (W x D), or: 1220mm xany length.

Thickness – Thickness of plate: 2mm / 3mm /4mm / 5mm (Panel thickness: 2mm / 3mm / 4mm/ 5mm).

– Aluminum Thickness: 0.06mm to 0.50mm(Aluminum thickness: 0.06mm to 0.50mm)

Standard paint system – recommended; PET(Polyethylene terephthalate) – For indoor applications / PVDF (polyvinylidene fluoride) – For outdoor applications.