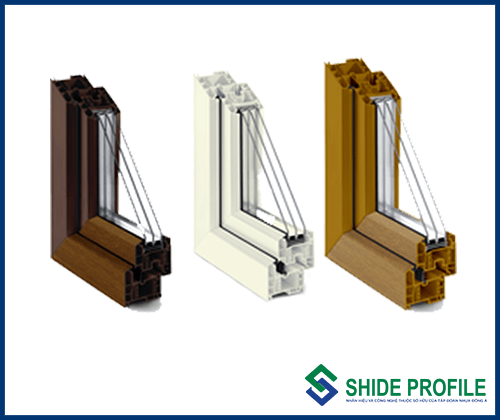

Shide profile color and wood grain

Detailed information Shide color – 3D wood grain

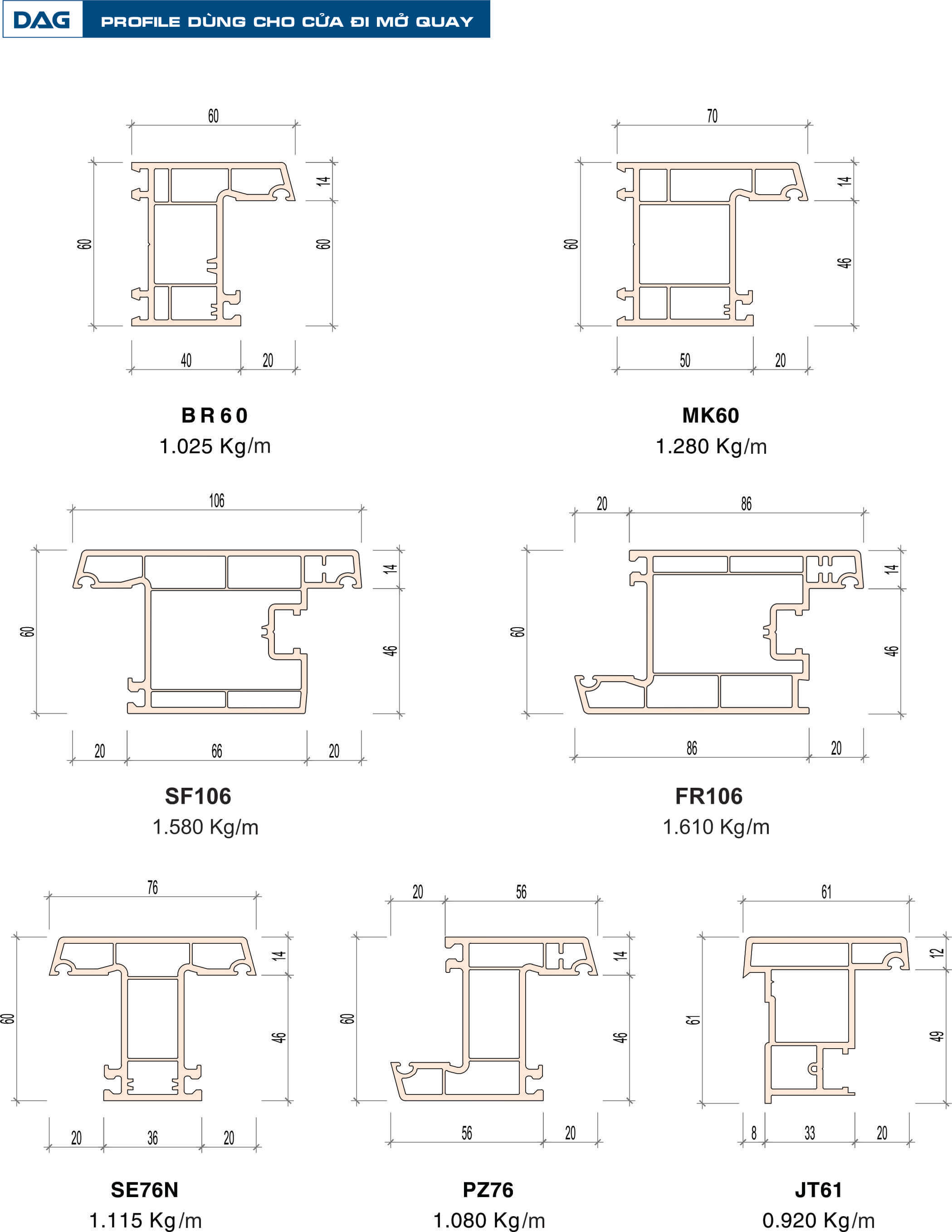

Product code: Shide M-G system 60

Specification: 5.8m & 6m long with different profiles

Colors: Solid color, ASA coating, 3D wood grain

Material; Unplasticized Poly Vinyl Chloride – Unplasticized synthetic vinyl, or non-plasticized PVC abbreviated uPVC

ASA-Polymer color coatings for extrusion ASA resins are a tertiary copolymers including Acrylonitrile, Styrene and Acrylate. ASA copolymer combines the high load capacity of acrylates and excellent weather resistance, chemical resistance and high hardness of acrylonitrile,

Thickness: outer contact surface from 2.2mm -2.8mm

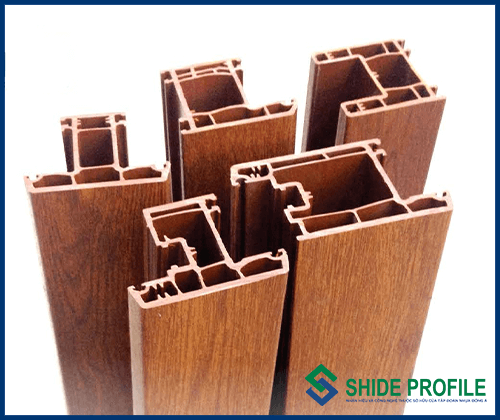

Application: The main material of uPVC door with reinforced steel core is constructed for office buildings, Trade Centers, Hotels, Apartments, Schools, Hospitals, etc.

Characteristics:

UPVC (Ultra PVC) is a high heat resistant plastic that is fire resistant up to 1000 degrees Celsius. Time to withstand melting heat is only 30 minutes. The uPVC plastic bar only melts, not ignites

Products with high durability, anti-aging, not deformed over time, no warping, termites and tight fitting, withstand high pressure …

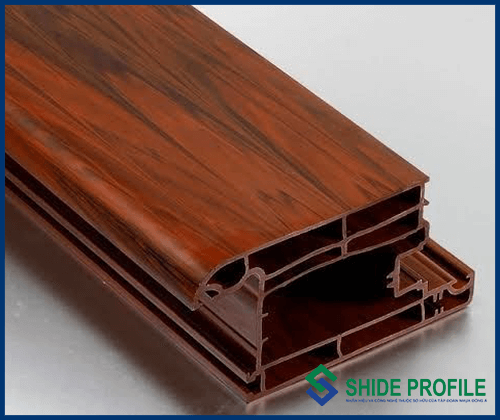

Description: Shide Profile has a box-shaped structure, divided into many empty compartments with sound and heat insulation functions, fitted with reinforced steel core to increase the ability to save force for the door structure. In addition, the empty space has the function of drainage ditch to prevent water from penetrating into the house.

UPVC Shide has a product line of uPVC color bar of raw material “ASA” with UV protection, 3D embossed, unleaded upvc bar manufactured on the latest “Greenline” technology with harmless ingredients of Calcium. Environmental friendly zinc and consumer health

Warranty: 12 years

Highclass UV-resistant uPVC product line:

This is a new type of high-end product called the same-color series, or the color-coded series. Highclass color plastic is manufactured using the most modern technology available today, using ASA thermoplastic materials. DAG color uPVC of various colors, differentiating from traditional white plastic doors is one of the best products on the market with many features, anti-UV performance, resistance Excellent weather resistance, heat resistance, outstanding noise resistance, good resistance to high temperatures, ASA’s very good mechanical and physical properties, so the rigidity of the product is very high.

The surface is made of luxurious, crisp texture lines with a new extrusion technology – The extruder and through the mold have rollers that create beautiful sand veins with one dark gray face and one Khaki gray face (two different colors on the same uPVC bar). This new technology is completely different from the old laminate technique (the surface of the product is not laminate).

UPVC plastic bar product line is manufactured on Greenline technology:

Manufactured according to European Union, German, French and British standards. This is the uPVC plastic bar product line that uses harmless materials of Zinc Calcium to replace the lead component that has been used very popular in the steel core plastic door industry to bring environmentally friendly and safe products. safe to health, users are not toxic to consumers, higher color fastness, less brittle.

Quality tested by ASTM standards, Shide profiles are 30% more impact resistant than other profiles. At the same time the profile product density drops below 2%, which is a great benefit for input production and lower production costs

Manufactured at Dong A Plastic Group (DAG) according to the extrusion process, the color profile and wood grain Shide products have a box-shaped structure, divided into several empty compartments, with an outer surface thickness of 2.3mm to 2 , 5mm.

PRODUCTION LINE OF COLOR AND WOOD PROFILE

.

.

//iammeek.com/wp-content/uploads/2017/09/thanh-shide-profile-kqtn-566×800.jpg